Call for Emergecy

507-381-7742

Cannabis Manufacturing Plants

This light industrial project was designed and built for a cannabis company in Southern Minnesota. The project was for 3,000 L of evaporative capacity and -50F extraction.

-

Client

Modern Designers

-

Category

Air Conditioning

-

Start Date

17th Feb 2017

-

End Date

21st March 2017

-

Project Value

$175650.00

-

Location

Waseca, MN

Light Commercial Chillers

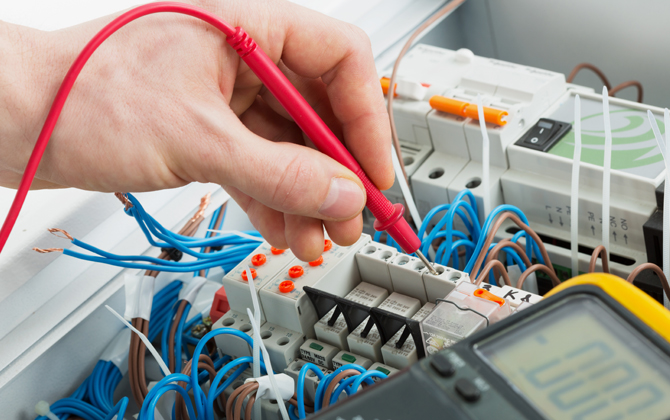

The project involved the installation of state-of-the-art chiller systems at a cannabis manufacturing facility in Southern Minnesota. The primary objective was to install the facility’s cooling components for extraction and distillation.

Initial Assessment and Planning:

- Conducted a thorough site evaluation to determine cooling requirements based on the facility’s size, layout, and operational needs.

- Collaborated closely with the client to understand specific needs, including temperature control precision, energy efficiency, and scalability for future expansion.

- Selected G&D Chillers for their reliability, energy efficiency, and compatibility with the client’s operational demands.

Design and Engineering:

-

- Customized the chiller system design to integrate seamlessly with the existing HVAC infrastructure.

- Developed detailed engineering plans, ensuring that the chiller system would meet the stringent environmental control requirements

Installation:

- Executed the installation of G&D Chillers, including setting up the chiller units, connecting them to the facility’s HVAC system, and integrating advanced control systems for precise temperature management.

- Coordinated with the facility’s operational team to minimize disruption during installation, ensuring that the project stayed on schedule.

Testing and Commissioning:

- Conducted comprehensive testing of the chiller systems to verify performance against the specified criteria.

- Fine-tuned the system to achieve optimal efficiency, ensuring consistent temperature control across the facility.

- Provided training to the client’s maintenance staff on the operation and upkeep of the new chiller systems.